24 April 2023

French Ambassador to the UK Hélène Duchêne visits Jellagen

22 February 2023

Secretary of State for Wales visits Jellagen

7 December 2022

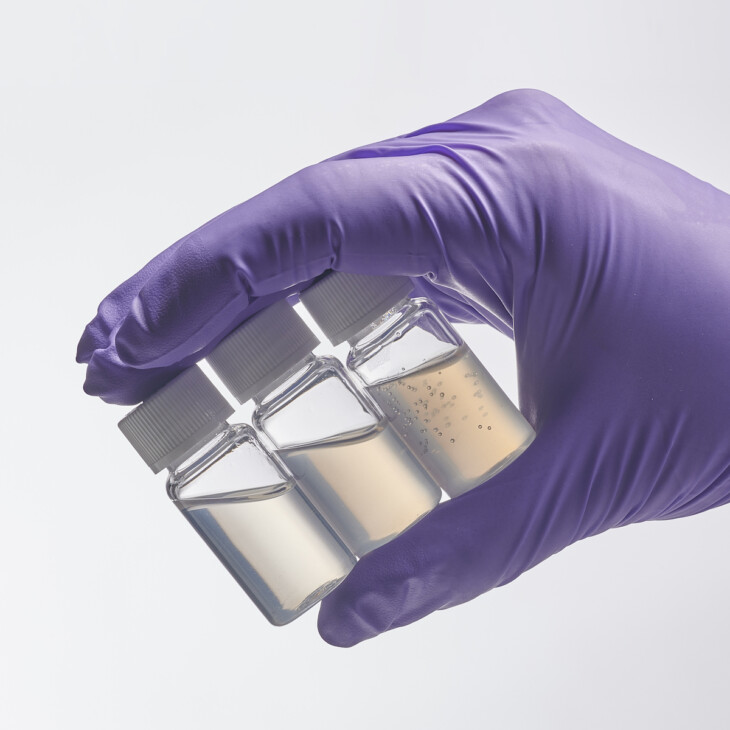

Jellagen closes £8.7m Series A funding round to accelerate development of Collagen Type 0 and revolutionise regenerative medicine

2 November 2022

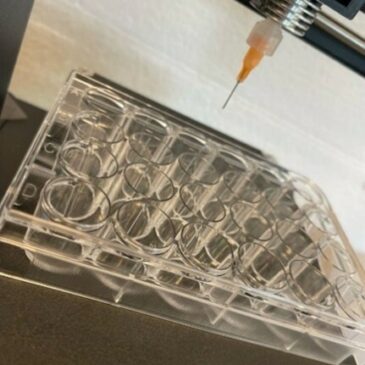

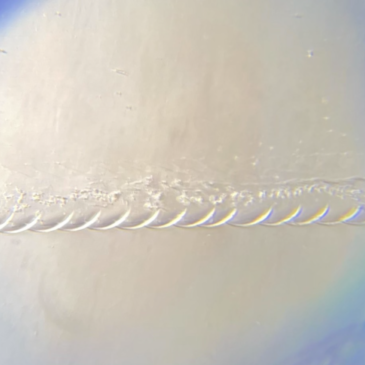

Copner Biotech and Jellagen Ltd awarded Innovate UK funding to develop game-changing 3D Inkjet Bioprinting Platform

29 September 2022